Nelson Valve Facilities

CASTING

FACILITY

The casting facility is the department within a valve manufacturing plant responsible for transforming molten metal into various valve components.

MACHINERY

FACILITY

Nelson Valve offers both on-site and subcontract machining services. We have the ability to machine any Valve we produce to meet our customer’s requirements.

FORGING

FACILITY

The forging facility at Nelson Valve plays a crucial role in creating high-strength, intricate components for industrial valves.

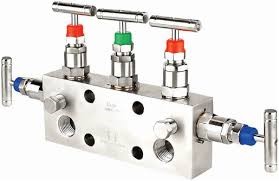

ASSEMBLING

FACILITY

Nelson valve is a contract manufacturer for “customer” designed valves, and our valves facility is well equipped with state-of-the-art machine shop having the latest machinery and skilled professionals experienced in valve manufacturing for over 3 decades.

We may not be the pioneers, but we are the leaders.

Customer satisfaction is our top priority at Nelson Valve.

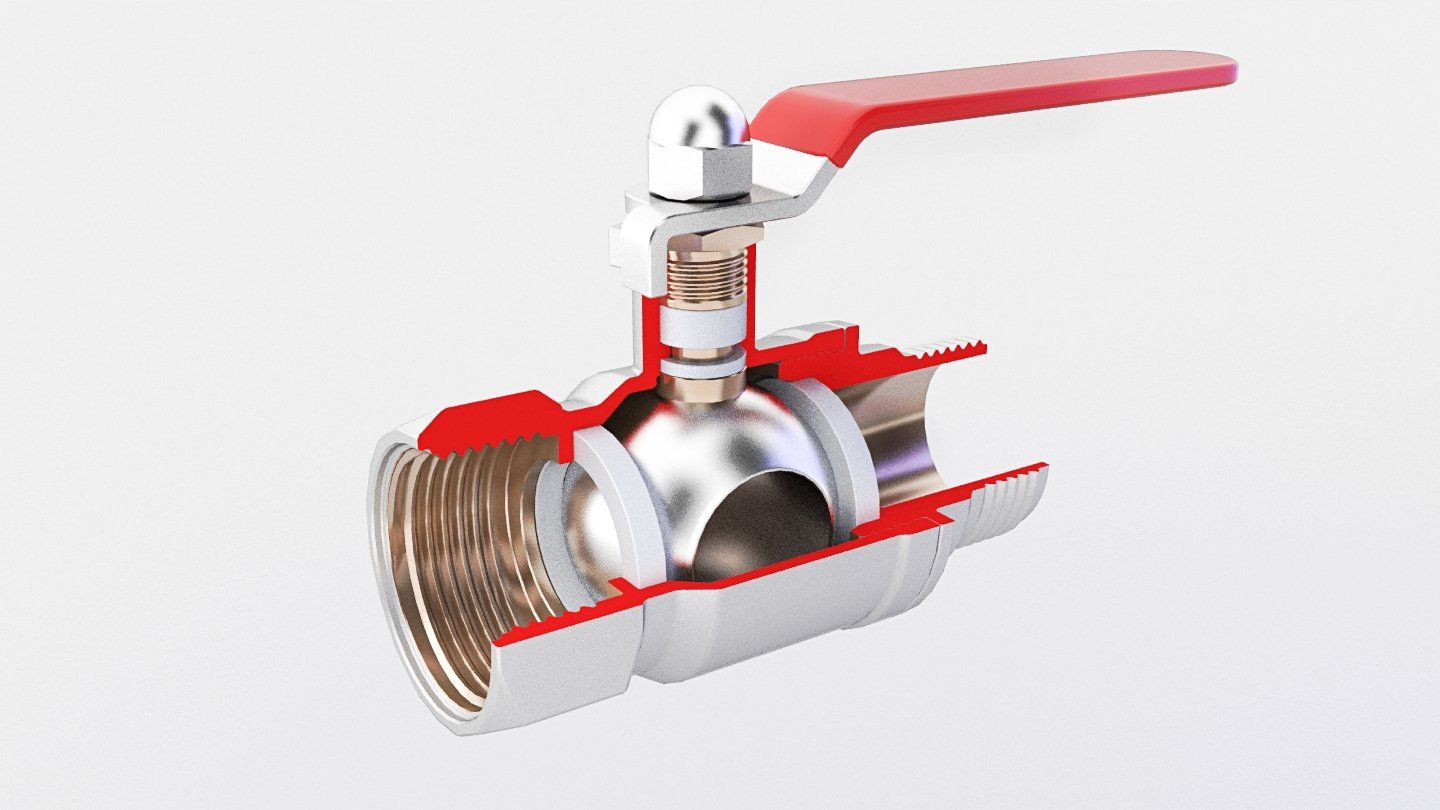

Nelson Valve

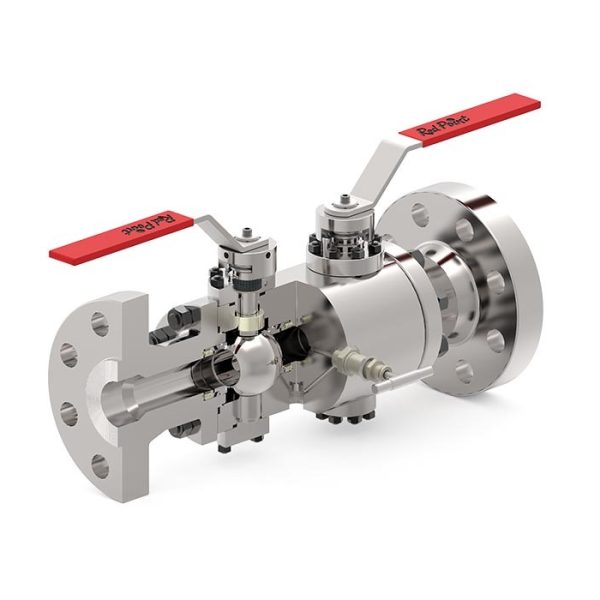

design and manufacture innovative valves

We believe that every application deserves a unique solution. at Nelson Valve, we’re dedicated to crafting innovative valves that meet your specific needs. With our comprehensive range of customized solutions, we ensure every application receives the perfect fit.

We Commit to Customer Respect:

- Reliable products and services

- Enhance engineering designs to ensure product performance

- Satisfaction of our customer, employee and supplier needs

- Product quality by using the latest technology and effective quality assurance

- Enhance productivity by optimizing management systems

- Consistently provide on-time services to our customers

- Train and develop talented people with strong work ethics to deliver effective performance