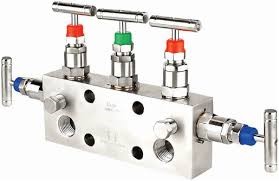

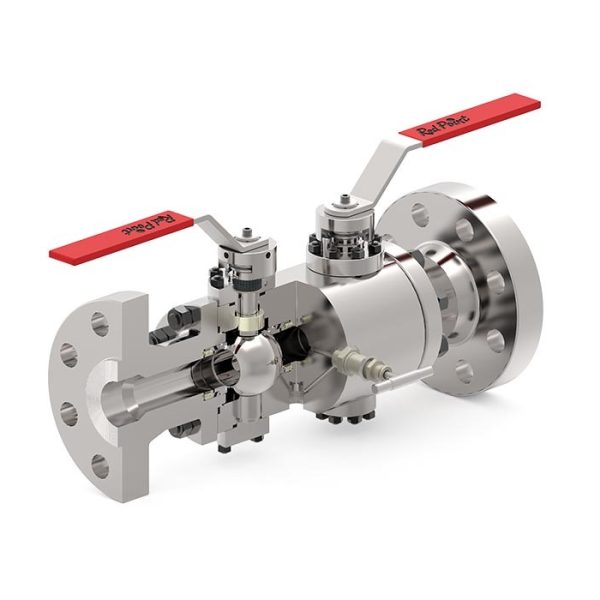

Material and Applications

While Nelson adheres to the following standards as a baseline, we continuously strive to exceed minimum requirements. We believe in designing each product specifically for your process conditions, ensuring seamless and trouble-free operation.

We specialize in manufacturing valves and pumps primarily from exotic alloys. Our extensive stock of specialty bar materials provides the flexibility needed for urgent valve or pump production. Beyond bar materials, we utilize forged rings and near-net-shape forgings in exotic materials to minimize machining costs.

Furthermore, to provide cost-efficiency for our clients, we are increasingly using "exotic material" cladding on standard grades. We are also happy to accommodate additional requirements upon request.

Benefits of the Nelson Production Method:

- Enhanced safety: Increased strength and wall thickness through the use of forged bars, rings, and near-net-shape materials.

- Cost-effective customization: We offer customized valve designs without compromising affordability.

- Unparalleled lead times: Experience unmatched speed in valve and pump production.

- Expertise in exotic alloys: Access a comprehensive range of specialized materials.

Special AlloysDuplex Super duplex | Stainless Steel304 (1.4301) 317L(1.4521) A351 CF8 A351 CF8M A351 CF3M A351 CG8M A351 CF8C | Low Alloy SteelA182-F5 A217 C5 A217 WC6 A217 WC9 | Carbon SteelA105 A216-WCA A216-WCB A216-WCC A352 LCB | Aluminum BronzeCuAl5 CuAl8 CuAl8Fe3 CuAl9Mn2 CuAl10Fe3 CuAl10Fe5Ni5 |

- Cryogenic

- High Temperature

- High Pressure

- Corrosive

- Nuclear

- Abrasive

- Fire Safe

- Sub Sea

- Acetic Acid

- Military