Research and Development ( R&D )

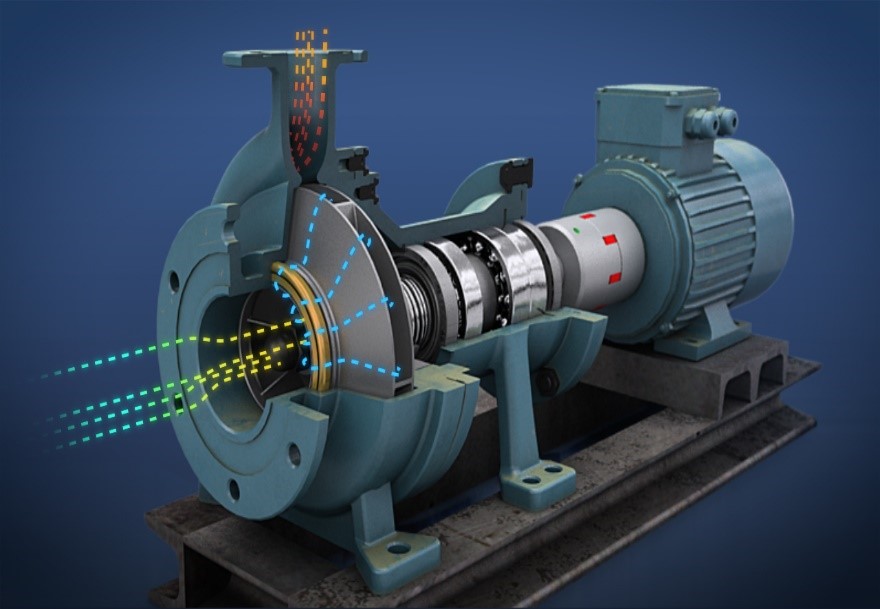

Our highly qualified and experienced engineering team forms the core of our R&D efforts. They excel in 3D molding design, finite element analysis, and CAD/CAM integration, providing tailor-made solutions for each unique application. To ensure the highest level of effectiveness and design flexibility, our team is equipped with sophisticated tools such as the 3D CAD system (Solid Edge) and FEMAP/Finite Element Method (FEM). Additionally, our in-house capacity testing loop allows for comprehensive flow and check valve performance evaluation.

Furthermore, we leverage cutting-edge simulation software to predict and optimize product performance before physical prototyping. This proactive approach minimizes development timelines and ensures our solutions meet the most rigorous standards.

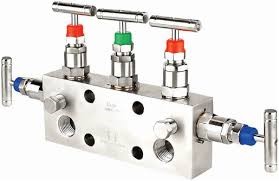

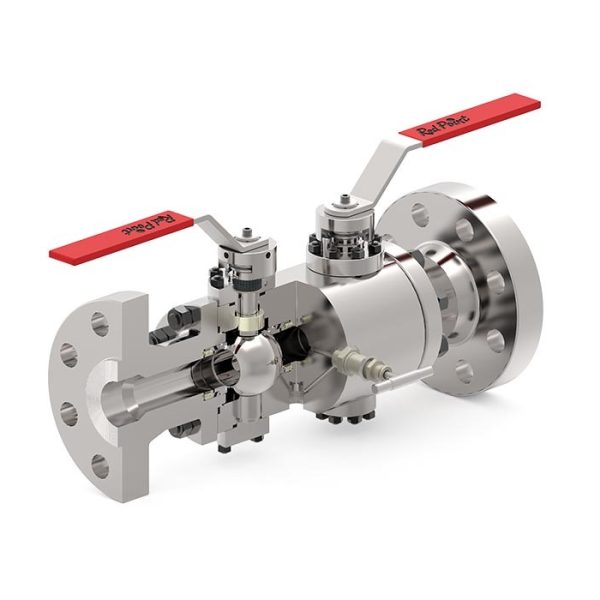

Our commitment to technology and innovation has established Nelson as a preferred supplier of cryogenic, low-emission, large-size, and high-pressure valves and pumps across the globe. We cater to diverse application needs and offer a wide range of materials, including exotic metallurgy, ensuring we have solutions for any valve and pump requirement.

This dedication to continuous improvement is evident in every product we produce. We leverage cutting-edge design, simulation, and analysis software to create 3D product designs. Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD) are utilized to optimize performance and enhance product reliability. Furthermore, rigorous testing procedures, both internally and at leading flow-control research facilities, guarantee that our customized solutions consistently meet and exceed customer expectations.

Nelson boasts comprehensive in-house qualification testing facilities, equipped to perform a variety of critical assessments, including:

- High-temperature and high-pressure gas testing

- In-house Qualification Test Facilities

- Endurance and cycle testing

- Fire testing

- Cryogenic testing

- Natural frequency testing

- Pipe-end load and reaction testing

- Vacuum testing

- Fugitive emission testing

- Static load simulation

These comprehensive capabilities ensure that our products deliver exceptional performance, reliability, and safety in even the most demanding applications.